HomeProductTension systemTension sensor

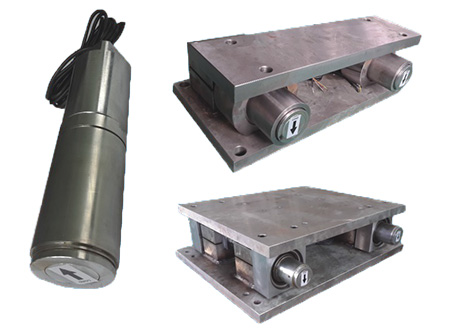

Heavy-duty tension sensor LDS series

Application Description:

LDS series tension sensor

Adopting today's advanced sensor technology, special anti-shear strain structure design and integrated full-sealed anti-corrosion design make the output linear, high response frequency, stable and durable. The perfect stress structure and manufacturing process enable it to achieve a tension detection range of 1: 1000, and can output high-sensitivity signals within the tension detection range.

Hotline:021-60892191 Message

- Product description

- Performance parameter

- Installation drawings

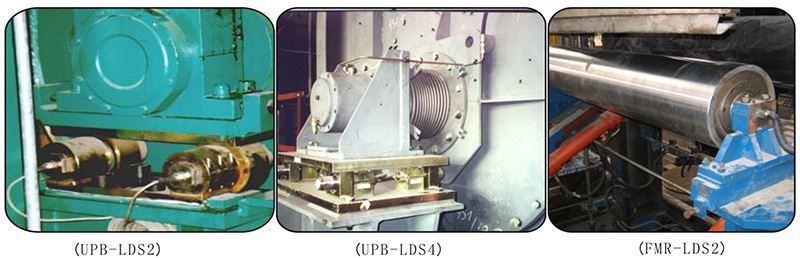

- Application site

- Download

LDS series tension sensor

Adopting today's advanced sensor technology, special anti-shear strain structure design and integrated full-sealed anti-corrosion design make the output linear, high response frequency, stable and durable. The perfect stress structure and manufacturing process enable it to achieve a tension detection range of 1: 1000, and can output high-sensitivity signals within the tension detection range.

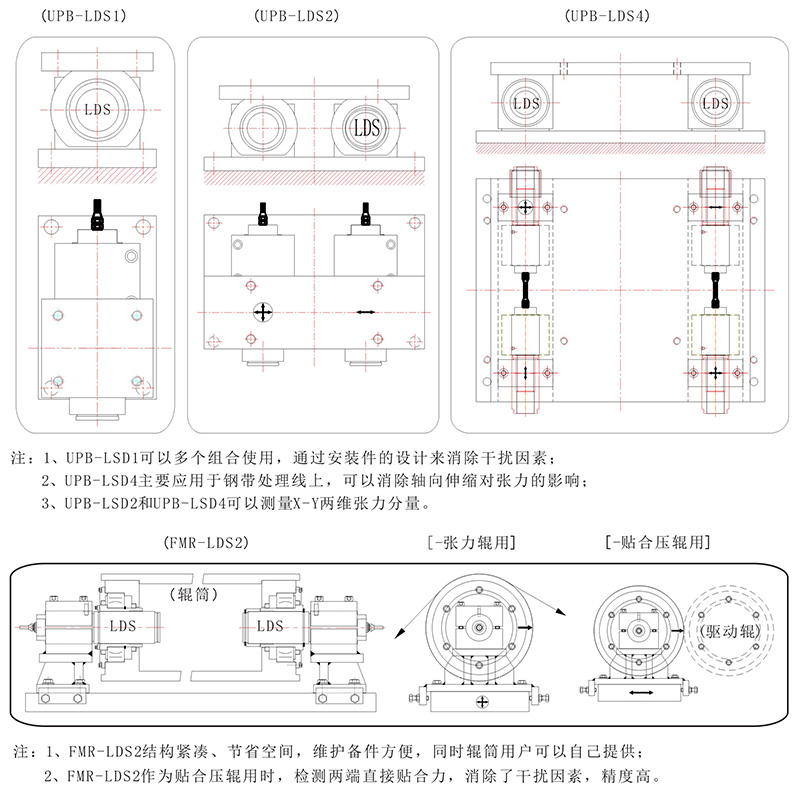

The LDS body has a round rod shape, which makes the installation of the user various and convenient. At the same time, the UPS sensor based on LDS can measure the two-dimensional tension component of the X-Y axis. With our instrument, it can be used in situations where the angle of the package changes.

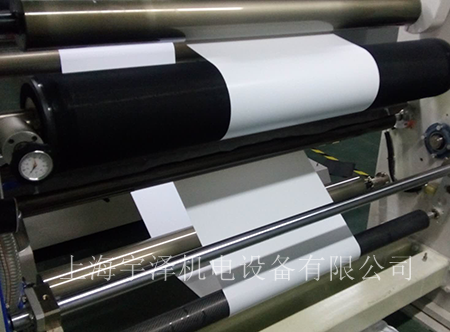

Widely used in: coiling control equipment and production lines such as printing, laminating, coating, die cutting, papermaking, rubber, textile, steel strip, wire and cable and film.

| Rated load(N) | |

| (LDS-M1)50500,1K,2.5K,5K | (LDS-M2)5K6K8K10K15K20K |

| (LDS-M3)30K40k50K | (LDS-M4)65K75K85K100K |

| (LDS-M5)100K150K200K500K | |

| Working power | DC5-18Vdc(recommend10Vdc) |

| Tension signal output | 0-20mV/0-250mV |

| Operating temperature | -10~+50℃(Safe temperature-40~+105℃) |

| Safety overload | 200%Rated Capacity(Lateral overload100%) |

| Sensor form | Resistance strain gauge |

| Linear error | ±0.012%(RC) |

| Repeatability error | ±0.01%(RC) |

| Comprehensive error | ±0.02%(RC) |

| Temperature drift | ±0.0015/℃(RO) |

| Sensor material | Precipitation stainless steel(USASI17PH) |

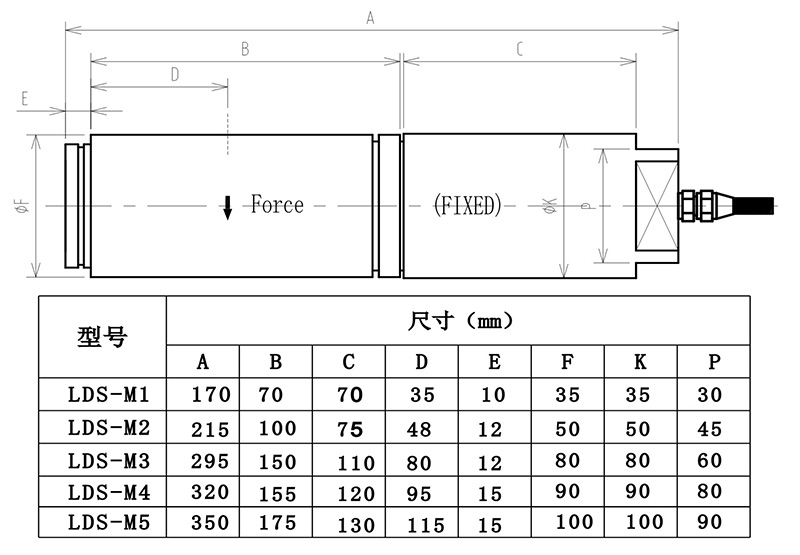

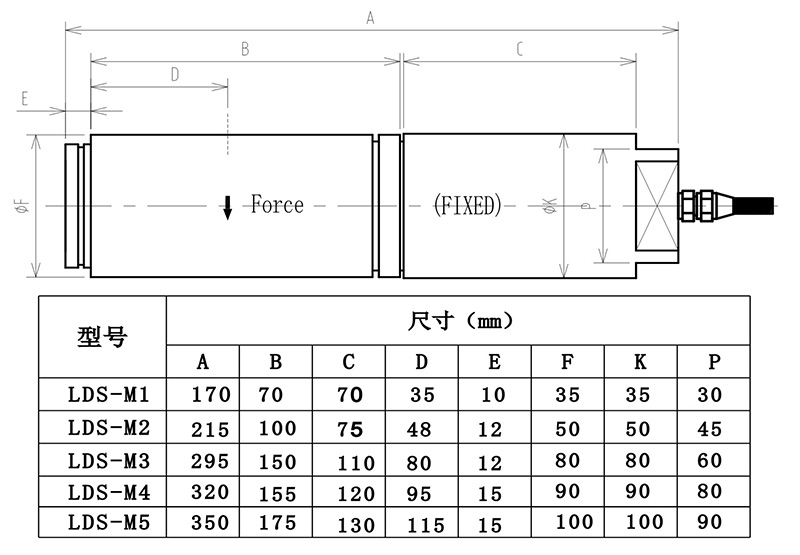

Installation size

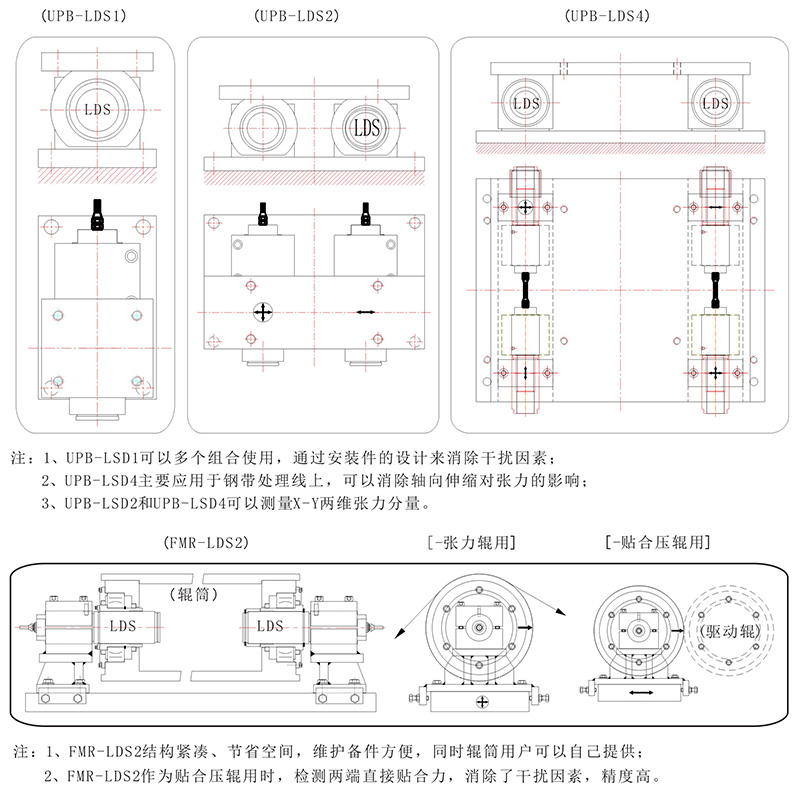

Installation method

Manual.pdf

Recommended News

-

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26