HomeProductTension systemTension sensor

Tension sensor UPB-M1 series

Application Description:

The upb series bearing pedestal-type tension sensor adopts advanced sensor technology and an integrally sealed and anti-corrosion design which makes the sensor's output linear good response speed corrosion resistance and dust resistance high stability and durable.

Hotline:021-60892191 Message

- Product description

- Performance parameter

- Installation drawings

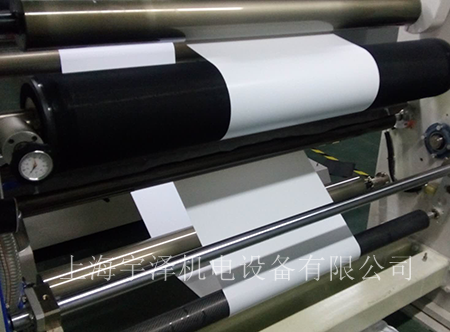

- Application site

- Download

The upb series bearing pedestal-type tension sensor adopts advanced sensor technology and an integrally sealed and anti-corrosion design which makes the sensor's output linear good response speed corrosion resistance and dust resistance high stability and durable. Foil strain gauges provide high sensitivity at low tension. Widely used in printing laminating coating die cutting paper making rubber textile steel strip wire and cable and film winding control equipment and production lines.

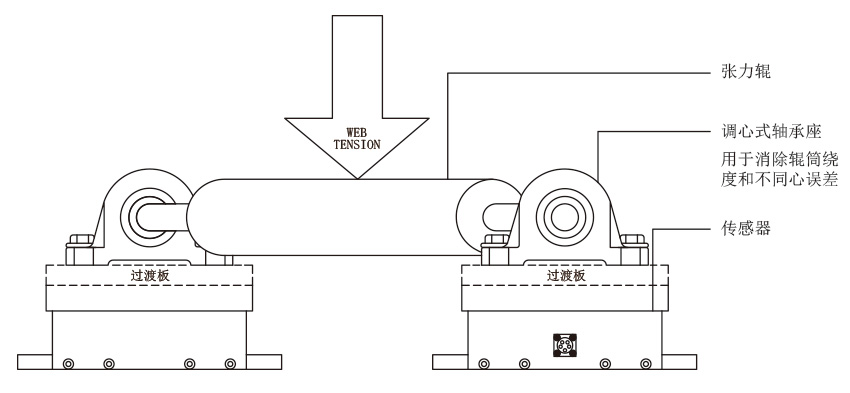

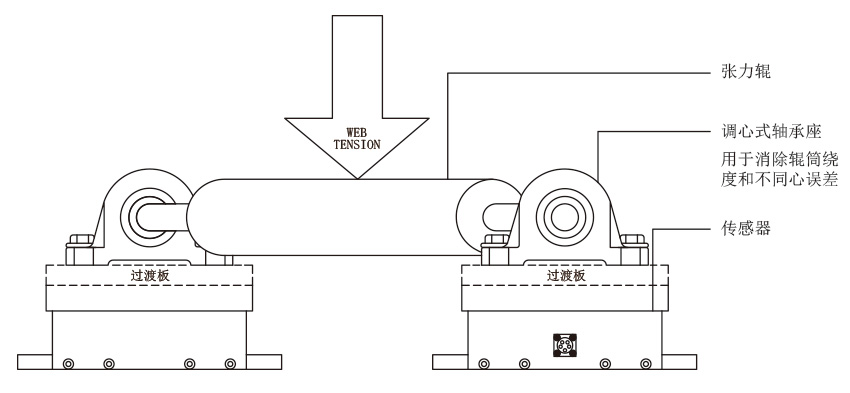

* Note: When installing the transition plate and bearing seat the tightening torque of the fastening bolts must not be too large so as not to affect the accuracy of the sensor or even damage the sensor. Fastening bolts can be glued to prevent loosening.

Features

● High response frequency and good linearity of output signal

● Built-in temperature compensation network small temperature drift

● Same high sensitivity to high and low tension

● Wide effective tension detection range up to 45: 1

● Maximum overload capacity can reach 1000%

● Installed under the bearing seat no moving parts

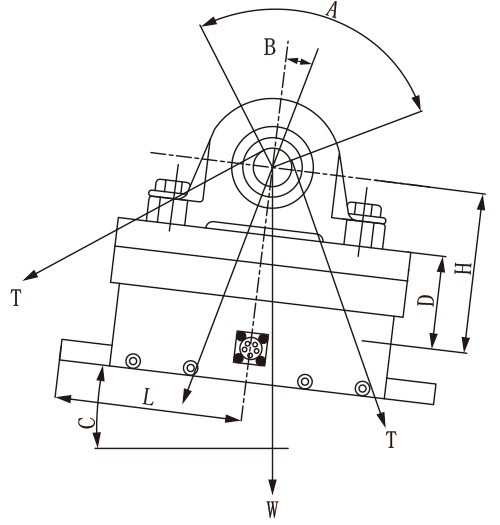

Calculation and selection of rated load

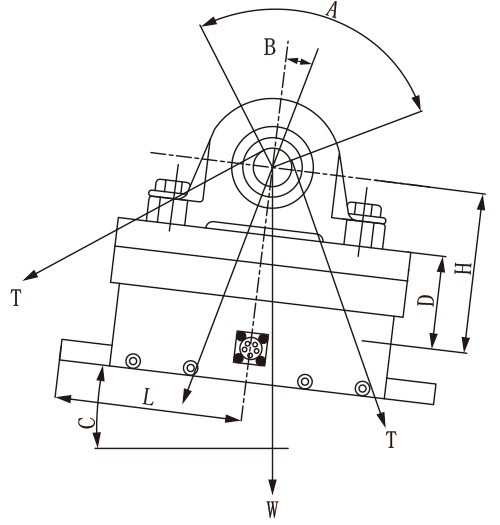

MWF * = ((2TXKXSIN (A / 2) X (HsinB + LcosB) soil W (LcosC-HcosC)) ** / (2L) MWF: maximum working pressure (N);

A: wrap angle (degrees); B: tension angle (degrees);

K: safety factor (1.4-2.0); T: maximum total tension (N); W: dead weight of the tension roller (N);

* MWF calculation result is the maximum working pressure endured by a single sensor

** If the B angle is below the horizontal line use "+" if the horizontal line is using "" _ "

| Working power | DC5-15V |

| Tension signal output | 0-20mV |

| Operating temperature | - 38°C ~+ 75C |

| Working humidity | <90%R.H. |

| Sensor form | Resistance strain gauge |

| Linear error | <土0.1% |

| Repeatability error | <+0.1 % |

| Comprehensive error | <土0.2% |

| Temperature drift | <土0.02%/°C |

| Connector specifications | aviationWS-12 |

| Sensor material | Special alloy |

| Sensor housing material | Gold alloy steel |

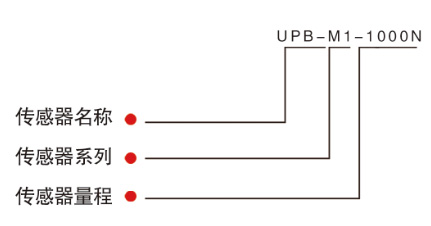

Order code (for example)

Product selection table

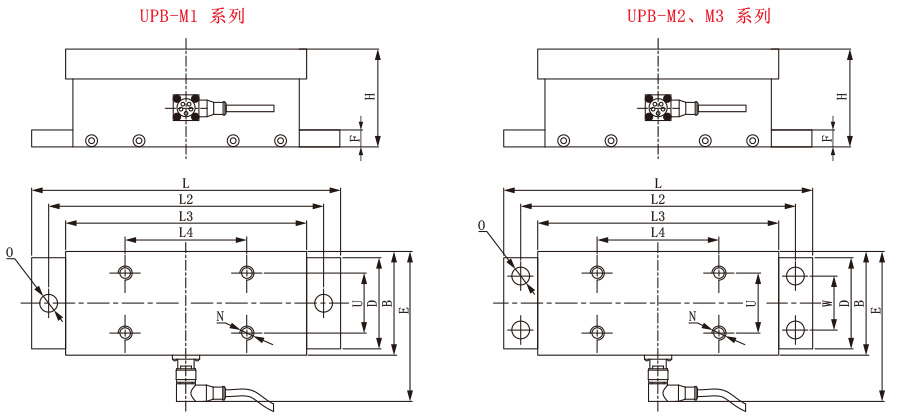

| model | Rated load(N) | Dimensions | ||||||||||||

| L | B | H | D | E | F | G | H | N | O | U | V | W | ||

| UPB-M1 | 500N | 228 | 76 | 72 | 65 | 88 | 12 | 203 | 178 | M10 | 12 | 44 | 70 | — |

| 1000N | 228 | 76 | 72 | 65 | 88 | 12 | 203 | 178 | M10 | 12 | 44 | 70 | — | |

| 2500N | 228 | 76 | 72 | 65 | 88 | 12 | 203 | 178 | M10 | 12 | 44 | 70 | — | |

| 5000N | 228 | 76 | 72 | 65 | 88 | 12 | 203 | 178 | M10 | 12 | 44 | 70 | — | |

Installation method

The UPB series sensor is mounted on the bearing block by a desktop shaft tension roller. The bearing block and the sensor are connected by a transition plate.

The UPB series sensor is mounted on the bearing block by a desktop shaft tension roller. The bearing block and the sensor are connected by a transition plate.

Manual.pdf

CAD.dwg

Recommended News

-

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26