HomeProductTension systemTension sensor

Tension sensor TGT series

Application Description:

TGT series cylindrical tension sensor adopts unique cantilever beam structure anti-thermal expansion and contraction mechanical structure high-performance analog circuit design. Under various dynamic online tension detection conditions the output signal has good fidelity fast response and high resistance. Strong interference ability.

Hotline:021-60892191 Message

- Product description

- Performance parameter

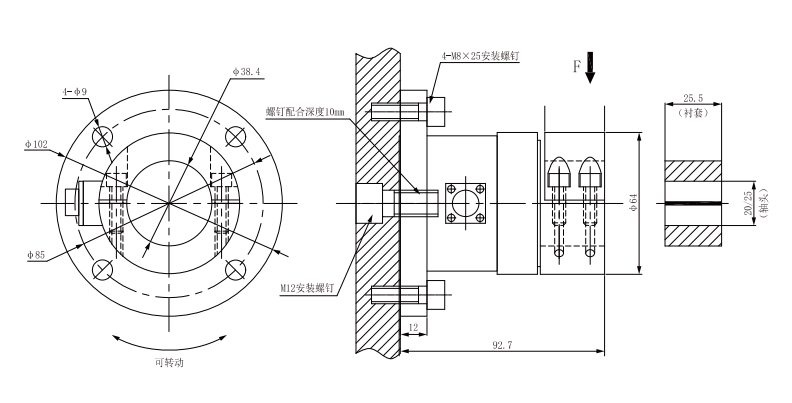

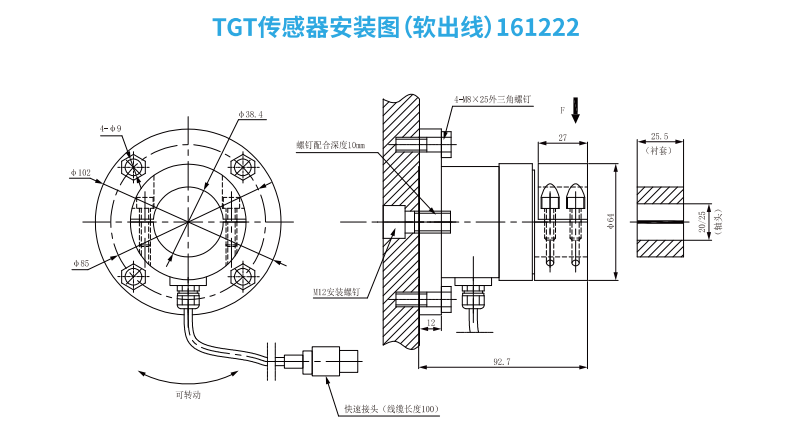

- Installation drawings

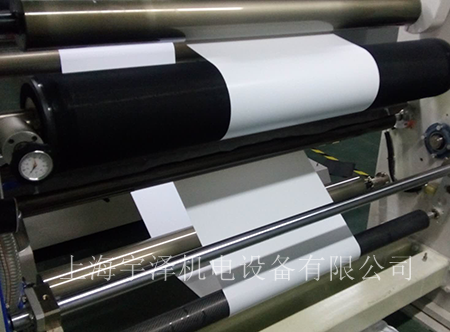

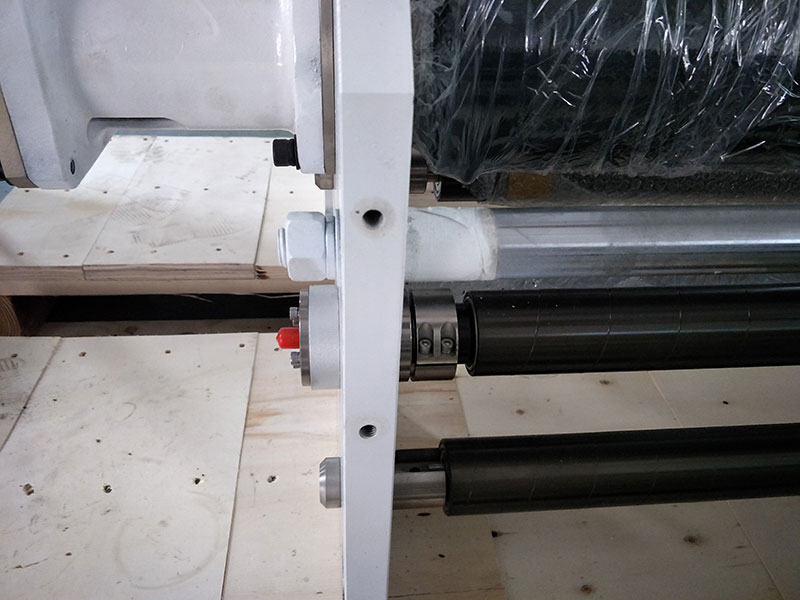

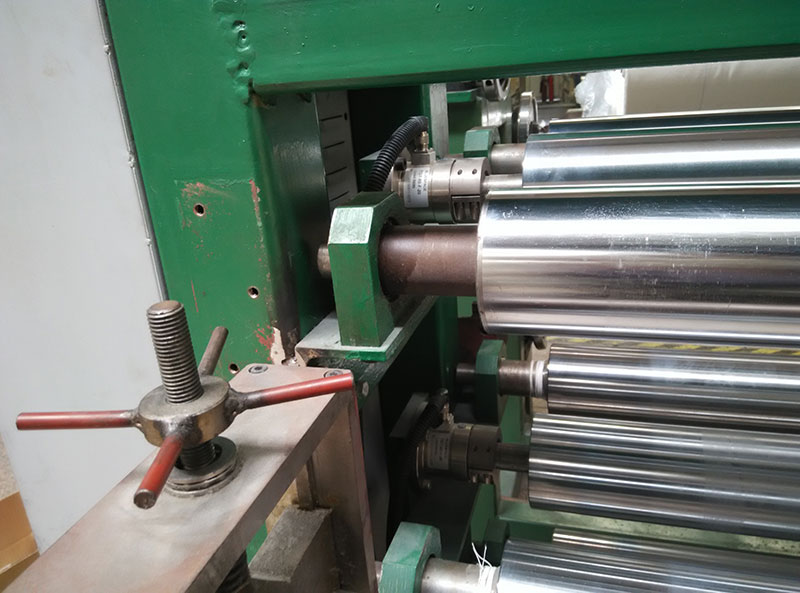

- Application site

- Download

TGT series cylindrical tension sensor adopts unique cantilever beam structure anti-thermal expansion and contraction mechanical structure high-performance analog circuit design. Under various dynamic online tension detection conditions the output signal has good fidelity fast response and high resistance. Strong interference ability.

TGT series tension sensors are rugged dust-proof corrosion-resistant high stability and constant sensitivity within the rated range. TGT series tension sensors have various specifications and installation methods and are generally used in coiling equipment such as brushes coating laminating machines die cutting machines paper machines wires and cables and other film.

TGT series tension sensors are rugged dust-proof corrosion-resistant high stability and constant sensitivity within the rated range. TGT series tension sensors have various specifications and installation methods and are generally used in coiling equipment such as brushes coating laminating machines die cutting machines paper machines wires and cables and other film.

Features:

1. Output signal response frequency is up to 25HZ;

2. Good linearity of output signal;

3. The temperature drift of the built-in temperature compensation network is small;

4.Special mechanical mechanism design can compensate the interference caused by the expansion and contraction of the tension roller coaxiality and disturbance;

5. Full range effective detection within the rated tension range;

6. Adopt special technology to ensure high bonding strength between strain gauge and substrate;

7. Built-in overload protection system of the sensor the overload capacity can reach 350%;

8. Industrial dust and corrosion protection process design;

| Working power | DC5-15V |

| Tension signal output | 0-20mV |

| Operating temperature | -38℃~+75℃ |

| Working humidity | <90%R.H |

| Sensor form | Resistance strain gauge |

| Linear error | <±0.1% |

| Repeatability error | <±0.1% |

| Comprehensive error | <±0.2% |

| Temperature drift | <±0.2%/℃ |

| Connector specifications | aviationWS-12 |

| Sensor material | Special alloy |

| Sensor housing material | alloy steel |

Manual.pdf

CAD.dwg

Recommended News

-

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26