HomeProductTension systemTension sensor

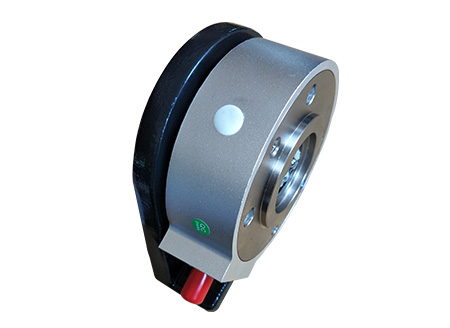

Tension sensor SLM series

Application Description:

SLM series ultra-thin tension sensor adopts water-proof dust-proof and anti-corrosion design. It has built-in bearings and can be installed with idler rollers or roller rollers. SLM series sensors have a small size.

Hotline:021-60892191 Message

- Product description

- Performance parameter

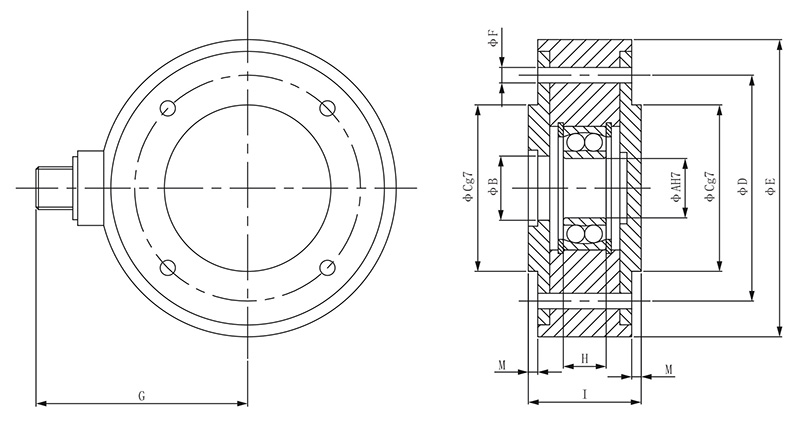

- Installation drawings

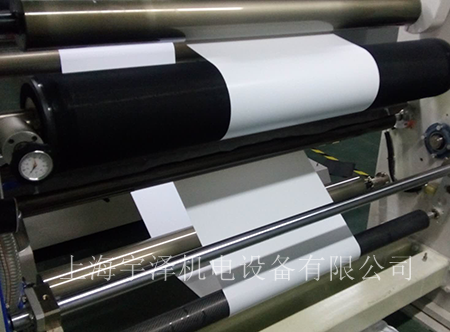

- Application site

- Download

SLM series ultra-thin tension sensor adopts water-proof dust-proof and corrosion-resistant design built-in bearings and can be installed with idler rollers or live rollers. SLM series sensors are compact especially suitable for places with limited space and can be directly installed on the device It can be installed on the equipment rack through the shaft stand or through the shaft pedestal. The shaft-through design makes it widely used in various winding equipment.

Features

● High response frequency of output signal

● Good linearity of output signal

● Built-in temperature compensation network small temperature drift

● Same high sensitivity to high and low tension

● Wide effective tension detection range up to 45: 1

● Adopt special technology to ensure high bonding strength between strain gauge and substrate

● Built-in overload protection system of the sensor the overload capacity can reach 500%

● Industrial dust and corrosion protection process design

● Special alloy durable

● The sensor adopts self-aligning ball bearing to eliminate the roller shaft winding degree and misalignment error

● Can be installed with idler roller or roller roller

| Working power | DC5-15V |

| Tension signal output | 0.-20mV |

| Operating temperature | 38℃~+75℃ |

| Working humidity | <90%R.H |

| Sensor form | Resistance strain gauge |

| Linear error | <±0.1% |

| Repeatability error | <±0.1% |

| Comprehensive error | <±0.2% |

| Temperature drift | <±0.2%/℃ |

| Connector specifications | aviationWS-12 |

| Sensor material | Special alloy |

| Sensor housing material | alloy steel |

产品选型表

| model | Rated load(N) | Dimensions | |||||||||

| A | B | C | D | E | F | G | H | I | M | ||

| SLM-10 | 250 | 12 | 16 | 50 | 70 | 100 | 6.5 | 86 | 14 | 36.5 | 3 |

| SLM-20 | 500 | 17 | 22 | 60 | 75 | 105 | 6.5 | 88 | 16 | 36.5 | 3 |

| SLM-30 | 700 | 25 | 31 | 70 | 95 | 125 | 6.5 | 98 | 18 | 47.5 | 4 |

| SLM-40 | 1000 | 35 | 44 | 100 | 135 | 175 | 8.5 | 123 | 23 | 65 | 4 |

| SLM-50 | 1500 | 35 | 44 | 100 | 135 | 175 | 8.5 | 123 | 23 | 65 | 4 |

| SLM-60 | 3000 | 65 | 44 | 100 | 135 | 175 | 8.5 | 123 | 23 | 65 | 4 |

| SLM-70 | 5000 | 65 | 80 | 160 | 220 | 265 | 10.5 | 168 | 33 | 80 | 4 |

| SLM-80 | 6000 | 65 | 80 | 160 | 220 | 265 | 10.5 | 168 | 33 | 80 | 4 |

| SLM-90 | 10000 | 65 | 80 | 160 | 220 | 265 | 10.5 | 168 | 33 | 80 | 4 |

| SLM-100 | 20000 | 65 | 80 | 160 | 220 | 265 | 10.5 | 168 | 33 | 80 | 4 |

| SLM-110 | 30000 | 65 | 80 | 160 | 220 | 265 | 10.5 | 168 | 33 | 80 | 4 |

| model | Rated load(N) | Dimensions | |||||||||

| d | A | B | C | D | E | F | G | H | I | ||

| SLM-10 | 250 | 50 | 140 | 115 | 56 | 109 | 40 | 25.25 | 12 | 10 | 9 |

| SLM-20 | 500 | 60 | 140 | 115 | 56 | 109 | 40 | 25.25 | 12 | 10 | 9 |

| SLM-30 | 700 | 70 | 170 | 140 | 67 | 130 | 45 | 32.75 | 16 | 13 | 11 |

| SLM-40 | 1000 | 100 | 240 | 195 | 90 | 178 | 70 | 47.5 | 22 | 19 | 18 |

| SLM-50 | 1500 | 100 | 240 | 195 | 90 | 178 | 70 | 47.5 | 22 | 19 | 18 |

| SLM-60 | 3000 | 100 | 240 | 195 | 90 | 178 | 70 | 47.5 | 22 | 19 | 18 |

| SLM-70 | 5000 | 160 | 340 | 290 | 137 | 270 | 100 | 62.5 | 28 | 24 | 22 |

| SLM-80 | 6000 | 160 | 340 | 290 | 137 | 270 | 100 | 62.5 | 28 | 24 | 22 |

| SLM-90 | 10000 | 160 | 340 | 290 | 137 | 270 | 100 | 62.5 | 28 | 24 | 22 |

| SLM-100 | 20000 | 160 | 340 | 290 | 137 | 270 | 100 | 62.5 | 28 | 24 | 22 |

| SLM-110 | 30000 | 160 | 340 | 290 | 137 | 270 | 100 | 62.5 | 28 | 24 | 22 |

Manual.pdf

CAD.dwg

3D.STEP

Recommended News

-

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26