HomeProductVacuum traction rollerVacuum traction roller

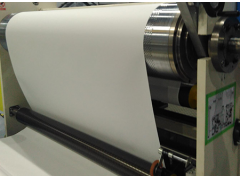

Vacuum traction roller

Application Description:

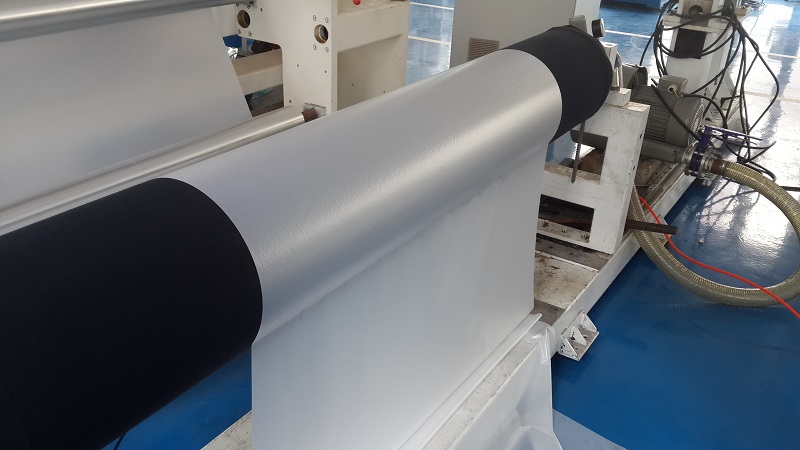

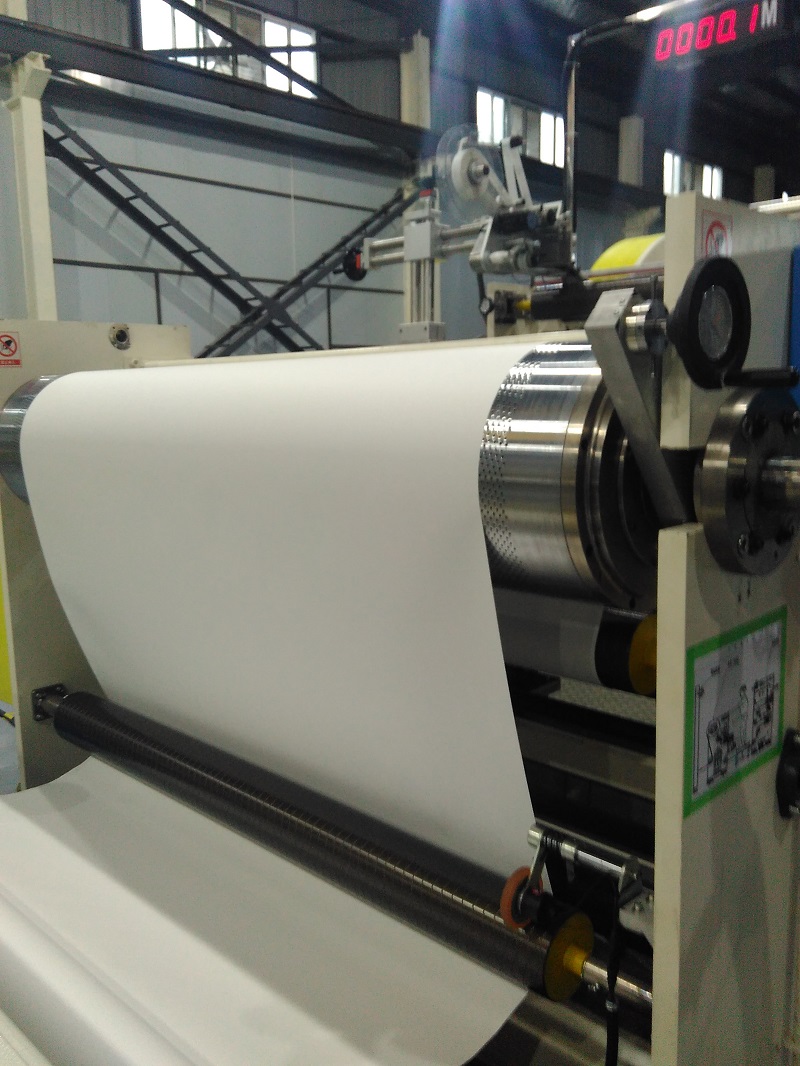

It is suitable for traction power rollers under high-precision tension control requirements of strip film (such as lithium battery diaphragm, lithium battery positive and negative electrodes, copper foil, aluminum foil, tape, protective film, hardened film, automobile explosion-proof film, etc.).

Hotline:021-60892191 Message

- Product description

- Performance parameter

- Installation drawings

- Application site

- Download

Purpose

It is suitable for traction power rollers under high-precision tension control requirements of strip film (such as lithium battery diaphragm, lithium battery positive and negative electrodes, copper foil, aluminum foil, tape, protective film, hardened film, automobile explosion-proof film, etc.).

Main advantage

● The tension is flexible before and after traction, and the isolation value can be adjusted by the negative pressure value;● The material does not need to be squeezed by the pressing roller to generate great traction;

● Realize the single-sided contact of the rubber material, effectively avoiding the damage of the rubber surface;

● Stabilize the position of the material to avoid the side slip of the material on the traction roller;

● Coupling the traction force with the tension difference, and the output tension can be zero;

● It can be hauled in both directions to meet the needs of special occasions;

Theoretical analysis

Patm-atmospheric pressure Pavc-negative air pressure

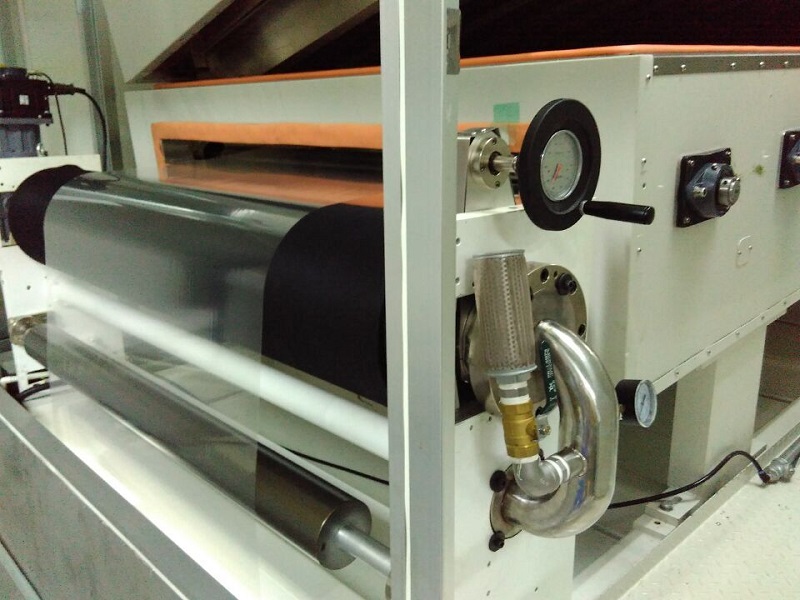

1. Drive support shaft: the reaction force support and air extraction function of the roller surface traction and rotation;

2. The traction is used for the roller surface;

3. The input tension is large, the output tension is small, and the torque traction is realized

4. Torque realization principle:

T=(Patm- Pvac) *S *f*R*K

(S) Roller surface area in vacuum zone (f) Coefficient of friction between the material and the roller surface

(R) Roller surface radius (K) Correction factor

| Main index |

| Surface finish of roller body:0.2-0.4um |

| Roll surface treatment: electroless plating/fine grinding/steel mesh/fiber sheath |

| Tension isolation density:0.1-0.3kgf/cm |

| Evacuation air volume:≤11.3cmm(The specific air volume is selected according to actual requirements) |

| Rated negative pressure:≤9-15KPa |

| Adapt to the line speed:≤550mpm |

| Roll surface:10-60℃ |

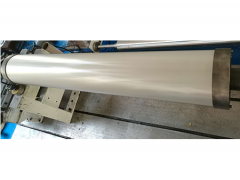

Roll surface specifications and treatment methods

| Roll surface treatment | Roller diameter (unit mm) | ||||||

| 160 | 200 | 204 | 260 | 318 | 324 | 420 | |

| Chrome plated fine grinding | ● | ● | ● | ● | ● | ● | ● |

| Stainless steel mesh | ● | ● | ● | ● | ● | ● | ● |

| High precision optical network | ● | ● | ● | ||||

| Fiber sheath | ● | ● | ● | ● | ● | ● | ● |

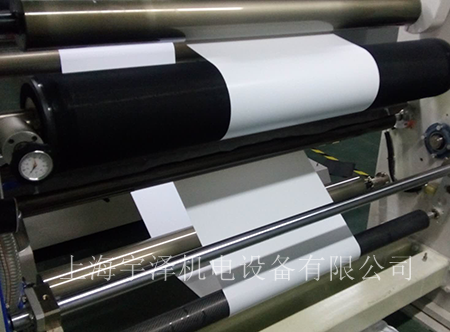

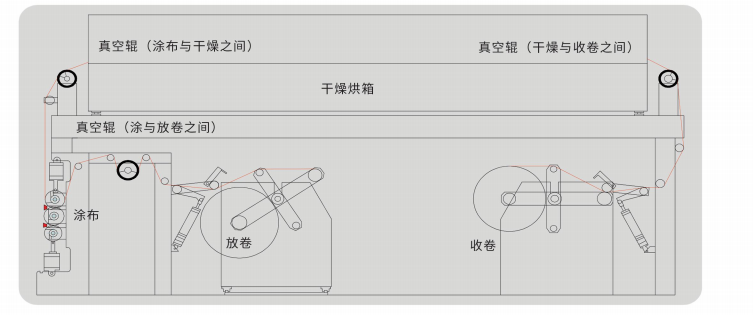

Partial application

[Coating machine] General optical film, optical tape, automotive film and other high-precision coating production lines.

Advantages:

1. After the material is glued, only the non-adhesive surface touches the roller to protect the rubber surface from damage;

2. Decoupling of tension and traction leads to achieve low tension or zero tension;

3. The traction is still effective when the material is worn for the first time or when the material is broken, and it is convenient to wear the material;

4. Other advantages are waiting for you to discover.

Manual.pdf

Recommended News

-

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26