HomeProductCorrection systemCorrection sensor

Ultrasonic probe

Application Description:

SS-RP ultrasonic sensor is an analog output sensor. It is mainly used for the correction control of coils. It is suitable for transparent and translucent materials. It is one of the main sensors for correction controllers.

Hotline:021-60892191 Message

- Product description

- Performance parameter

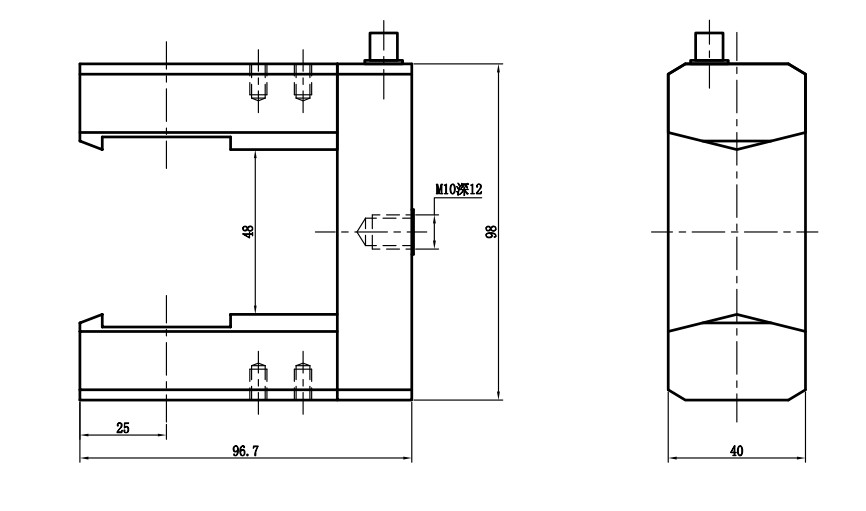

- Installation drawings

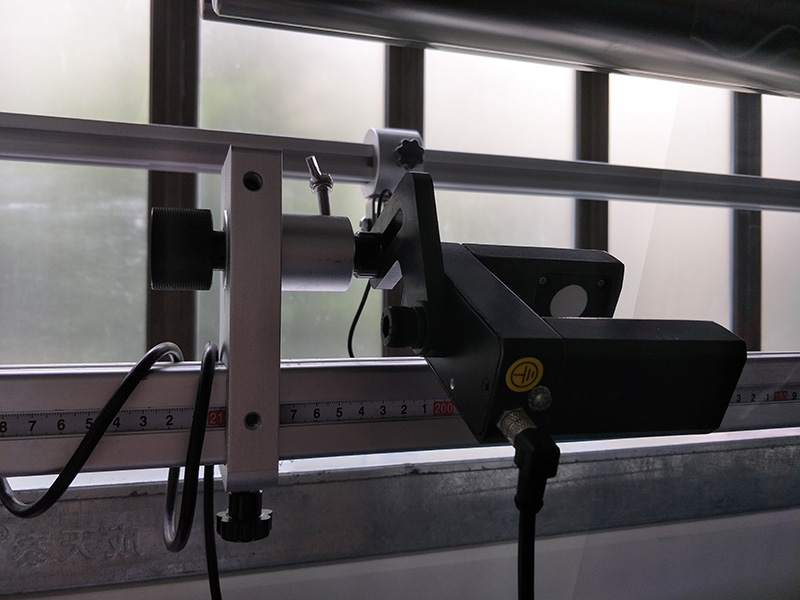

- Application site

- Download

SS-RP infrared sensor is an analog output type sensor, which is mainly used for the correction control of coils. It is suitable for transparent and opaque materials.

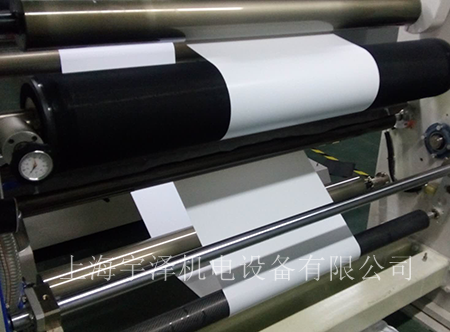

This type of sensor is mainly used for edge / center correction control of coils. It is suitable for opaque or transparent materials. Is now widely used in rewinding machines, laminating machines, slitting machines, coating machines and other equipment, winding and unwinding correction control.

Features:

This type of sensor is a square reflective photoelectric sensor, which is mainly used for the edge / following and correction control of coils. It is suitable for opaque materials or transparent materials.

Is now widely used in rewinding machines, laminating machines.

| project | specification |

| Correction controller | SS-RP(SU/E) |

| Dimensions (length x width x height) | 96.7x40x98mm |

| Working power | +12V 30mA |

| scope of test | 16mm |

| Detection method | On shot |

| output method | 0-5V(Analog voltage output) |

| Detection accuracy | ≤±0.01mm |

Manual.pdf

CAD.dwg

3D.STEP

Recommended News

-

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26